FLEXAN - STIFFENER FOR LEATHER BAG - 0.8mm - Texon Equivalent - 100X150cm SHEETS

FLEXAN - STIFFENER FOR LEATHER BAG - 0.8mm - Texon Equivalent - 100X150cm SHEETS

Couldn't load pickup availability

STIFFENER FOR LEATHER BAGS - BAG REINFORCEMENT - INTERFACING

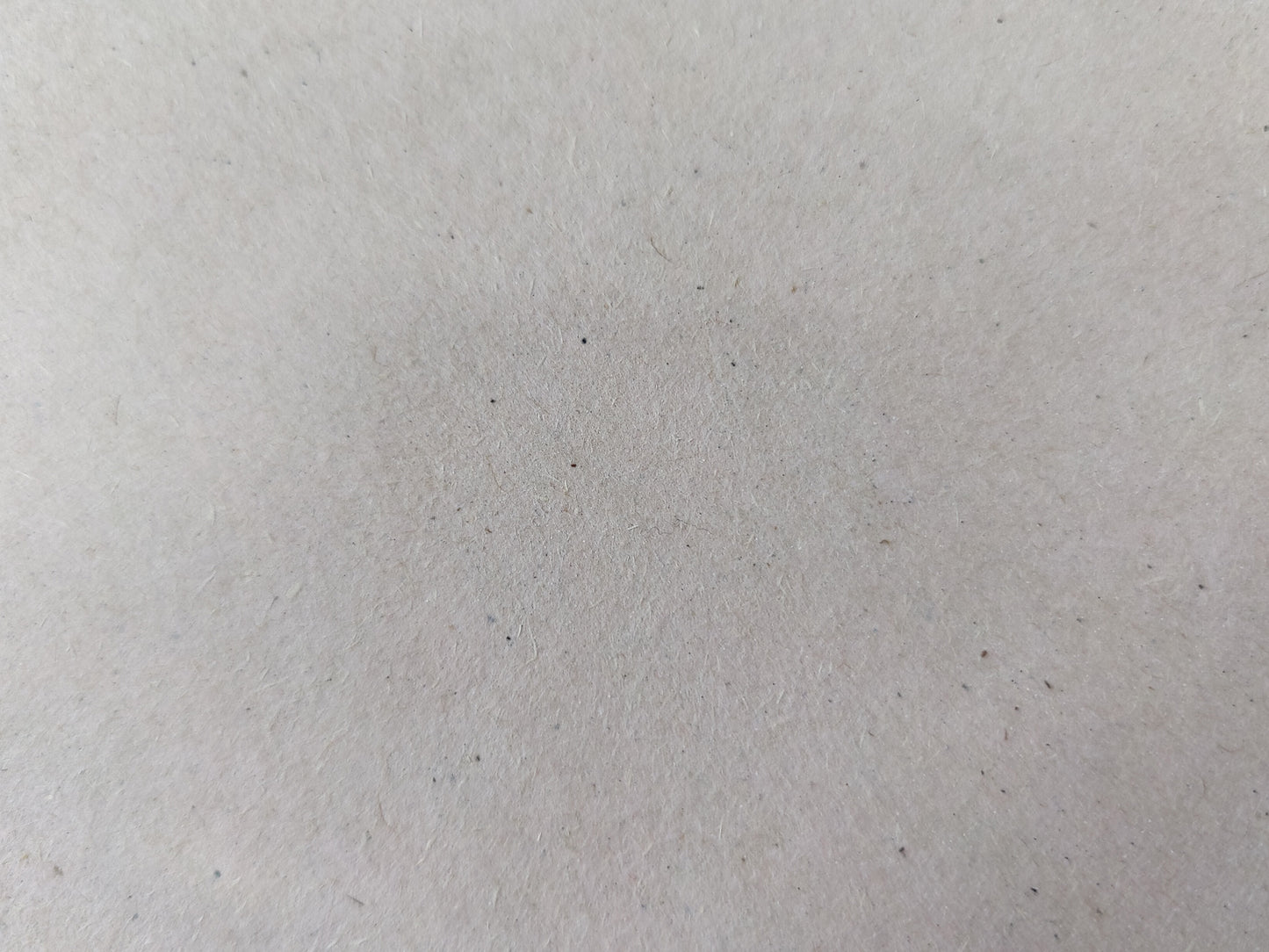

DESCRIPTION: Stiff cellulosic bag reinforcement with a paper-like feel.

Available in 100x150cm sheets and assorted colours.

USE: This cellulosic material stiffener is very similar to the more popular Texon or Bontex.

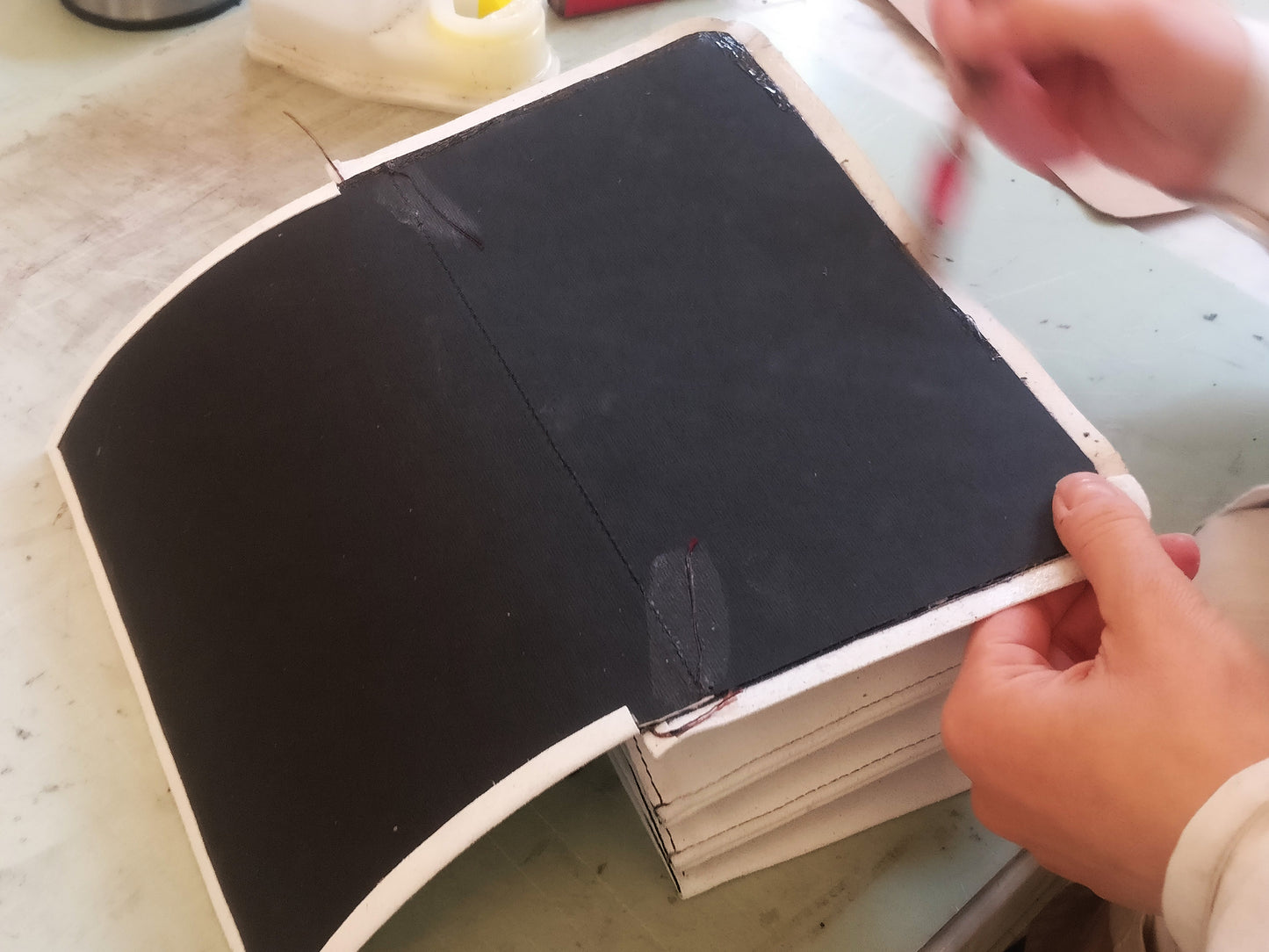

It is primarily used to reinforce and shape the body, backs, bottoms and flaps of bags.

Like SALPA (bonded leather), it can be skived to achieve specific thicknesses in certain areas.

Glue can be applied by spraying, brushing, or spreading.

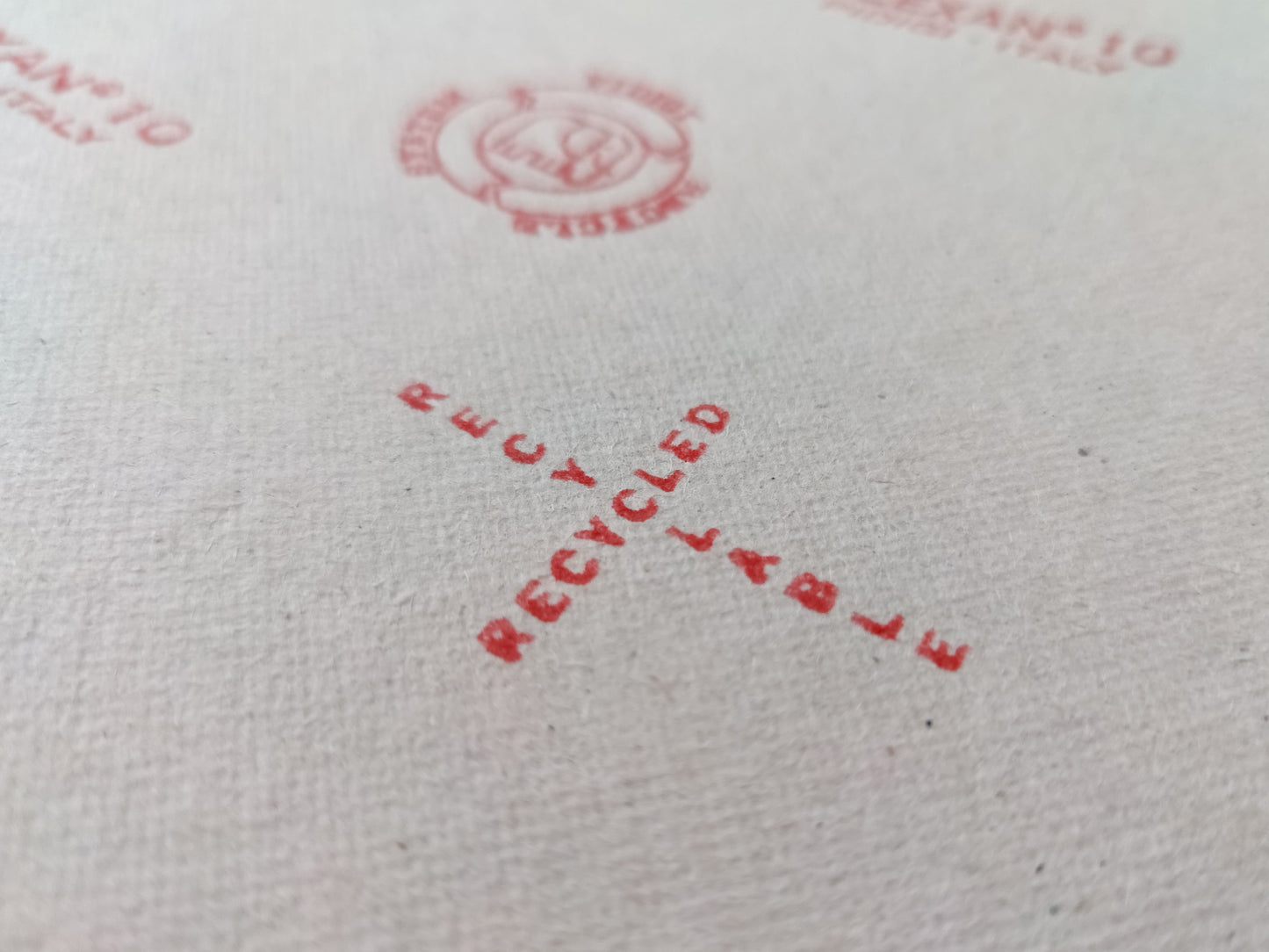

100% recyclable.

If you are looking for a thinner and lighter cellulosic stiffener for leather bags, please check CELLSAN.

SHEET SIZE: 100x150cm

COLOUR: Assorted

THICKNESS: 0.8mm

COMPOSITION: Cellulose (50% recycled fibers)

ORIGIN: Manufactured in Slovenia in an Italian-owned factory

WHAT'S THE BEST INTERFACING FOR BAG MAKING?

WHAT'S THE BEST INTERFACING FOR BAG MAKING?

Choosing the best interfacing for bag making depends on several factors, including the area of application, the material to be reinforced and the specific design of the bag.

Different materials have varying temperaments and weights, making them suitable for diverse structural needs.

Whether you need to reinforce stitching, prevent tearing or stretching in stress areas, or provide structure to specific areas of the bag, each type of reinforcement or leather stiffener serves a unique purpose.

Choose a bag making or leather stiffener or interlining and learn more about the types of reinforcements we stock

HOW TO APPLY A BAG MAKING/LEATHER STIFFENER

HOW TO APPLY A BAG MAKING/LEATHER STIFFENER

Interlining can be applied in various ways depending on the type.

Unlike fabrics, where some types of interfacings can be sewn directly onto the fabric, regular interlining for leather goods requires glue or adhesive spray for application.

Thermo adhesive interfacing, also known as fusible interfacing, is activated by heat and pressure, typically applied using an iron or a press machine.

This method bonds the interfacing to the material, providing a strong and permanent hold.

Self-adhesive interfacing, on the other hand, has an adhesive backing that sticks to the material when pressure is applied, eliminating the need for additional glue or heat.

SHIPPING INFORMATION

SHIPPING INFORMATION

LEAD TIME: We ship the orders within 3 working days using a tracked standard delivery service (3-5 working days delivery time).

TRACKING: Once your parcel has been shipped, you will receive an email with your tracking number.

COST: The shipping price is calculated at checkout.