NON WOVEN SELF-ADHESIVE STIFFENER FOR BAG MAKING - 70-150gsm - black/white

NON WOVEN SELF-ADHESIVE STIFFENER FOR BAG MAKING - 70-150gsm - black/white

Couldn't load pickup availability

STIFFENER FOR LEATHER BAGS - BAG REINFORCEMENT - INTERFACING

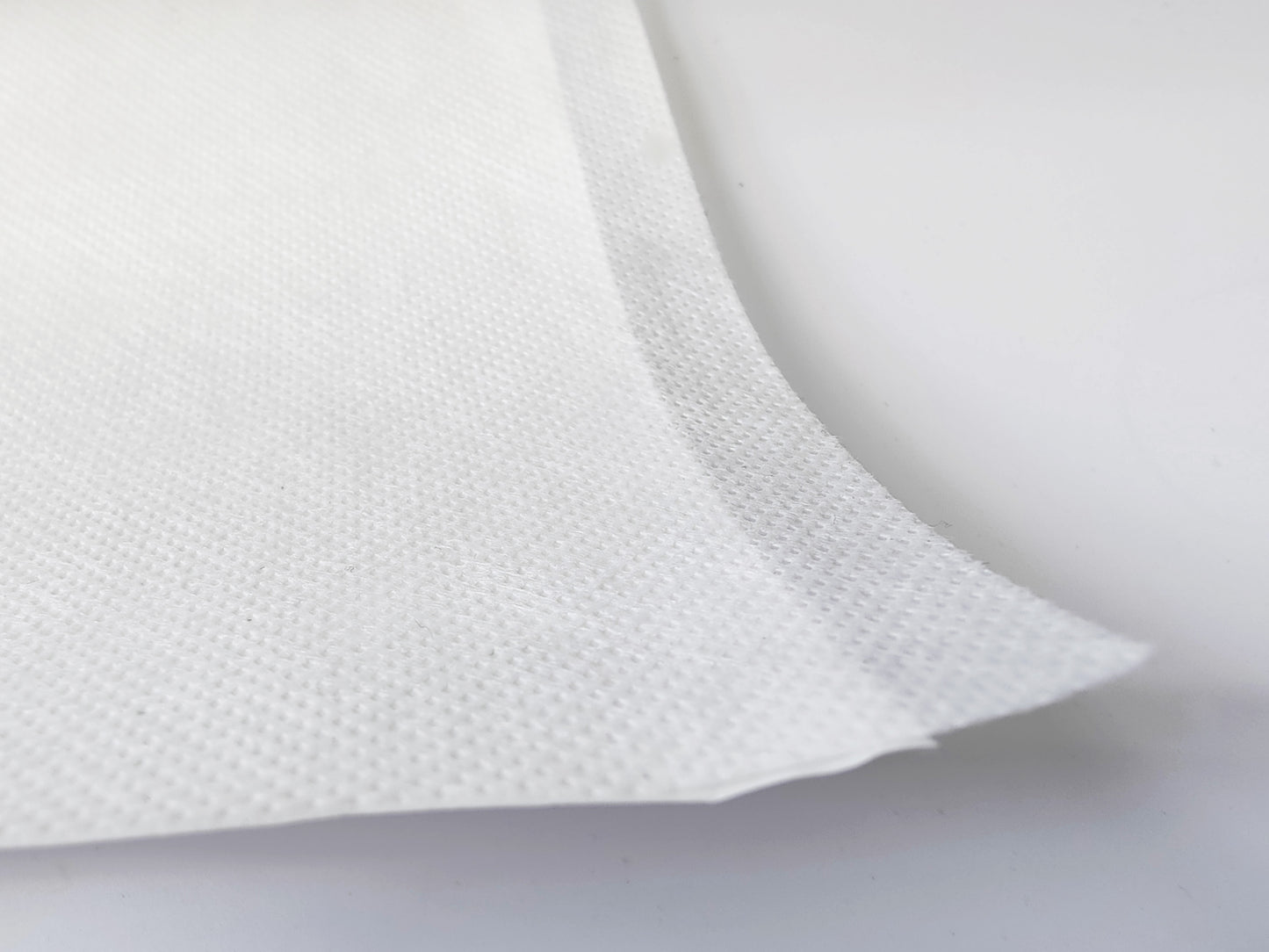

DESCRIPTION: Self-adhesive non-woven stiffener for bag making, leather goods and footwear also known as TNT reinforcement (Tessuto-Non-Tessuto, Italian for non-woven fabric). Supported on paper.

USE: This lightweight reinforcement for bags and accessories presents good tensile tear strength and is ideal for providing structure to stretchy fabric and leather.

Additionally, it can serve as a barrier when glueing fabric that would otherwise allow liquid glue to seep through to the other side.

Available in two differnt weights/colours.

Please note that any of our bag making stiffereners are always cut by the metre. For example, if you order 3 metres, you will receive 3 separate 1-metre pieces, not one continuous 3-metre length.

If you wish to receive a continuous piece, please get in touch before purchasing and we will provide a bespoke shipping quote.

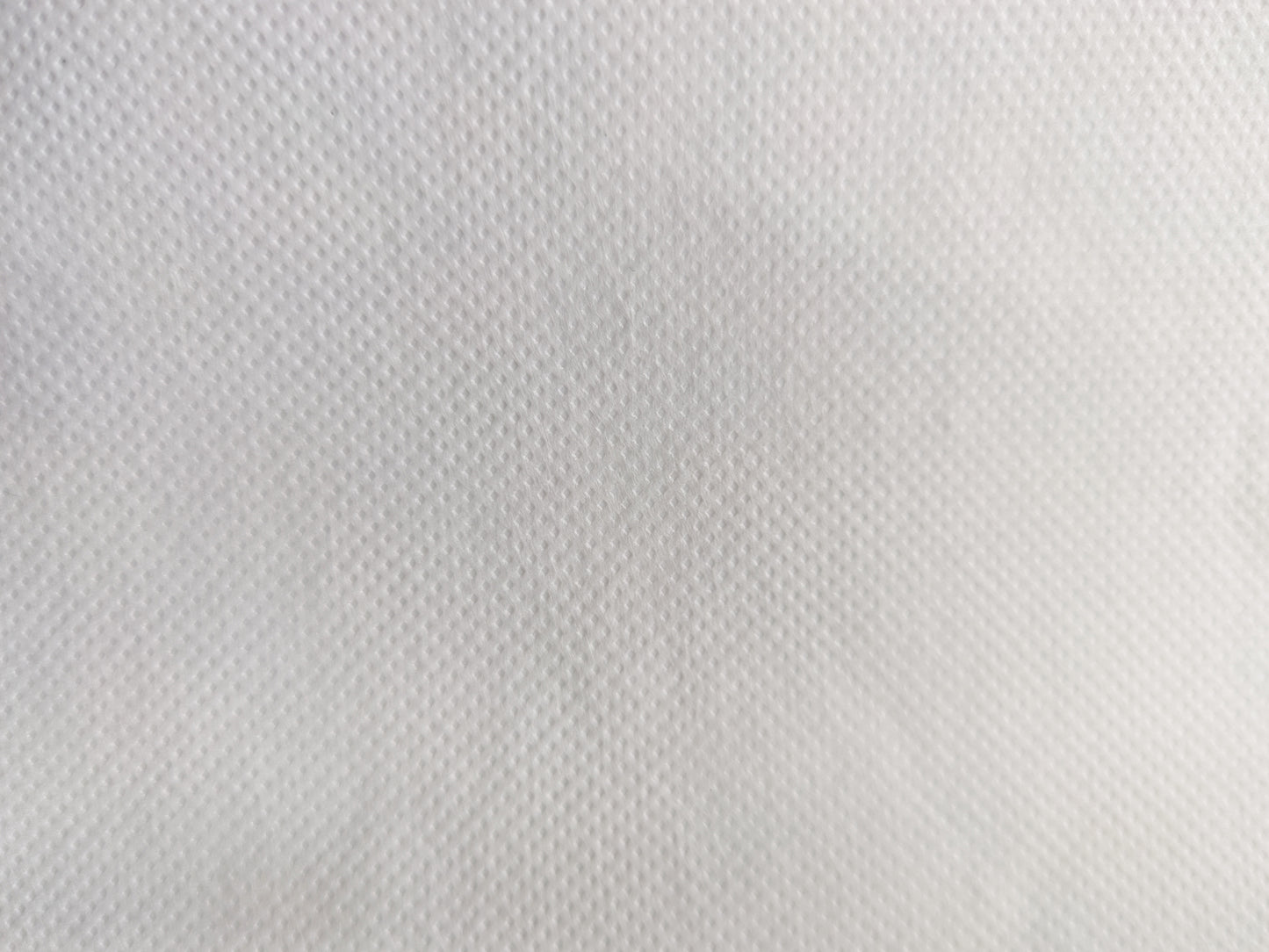

THICKNESS: 70 g/m2 - 150g/m2

COLOUR: Black - White

ROLL HEIGHT: 150cm

COMPOSITION: Polypropylene

ORIGIN: Italy

WHAT'S THE BEST INTERFACING FOR BAG MAKING?

WHAT'S THE BEST INTERFACING FOR BAG MAKING?

Choosing the best interfacing for bag making depends on several factors, including the area of application, the material to be reinforced and the specific design of the bag.

Different materials have varying temperaments and weights, making them suitable for diverse structural needs.

Whether you need to reinforce stitching, prevent tearing or stretching in stress areas, or provide structure to specific areas of the bag, each type of reinforcement or leather stiffener serves a unique purpose.

Choose a bag making or leather stiffener or interlining and learn more about the types of reinforcements we stock

HOW TO APPLY A BAG MAKING/LEATHER STIFFENER

HOW TO APPLY A BAG MAKING/LEATHER STIFFENER

Interlining can be applied in various ways depending on the type.

Unlike fabrics, where some types of interfacings can be sewn directly onto the fabric, regular interlining for leather goods requires glue or adhesive spray for application.

Thermo adhesive interfacing, also known as fusible interfacing, is activated by heat and pressure, typically applied using an iron or a press machine.

This method bonds the interfacing to the material, providing a strong and permanent hold.

Self-adhesive interfacing, on the other hand, has an adhesive backing that sticks to the material when pressure is applied, eliminating the need for additional glue or heat.

SHIPPING INFORMATION

SHIPPING INFORMATION

LEAD TIME: We ship the orders within 3 working days using a tracked standard delivery service (3-5 working days delivery time).

TRACKING: Once your parcel has been shipped, you will receive an email with your tracking number.

COST: The shipping price is calculated at checkout.